Most of us don’t realize how heavy a garage door is until we have to deal with one whose spring has broken, professional installers excepted. When the spring springs (usually when you’re leaving for work) you have to go about the tedious business of disconnecting the garage door opener, heroically heaving open the door, backing out the car, and running for your life when the full weight of the door comes crashing back down. It is then that you learn just how much these things weigh.

And when it comes time to replace that broken spring, getting the right size is crucial. Too small, and the automatic opener struggles to perform its eponymous task. Too large, and the door is hard to close. An effective garage door spring supplies just enough upward force to make a large steel door featherweight to operate and make you feel like a superhero.

I bring this up because understanding how to balance your home draft system is a lot like choosing a garage door spring. In fact, it’s fundamentally the same thing.

Opposing forces

Just like a garage door, a well-designed draft system successfully balances two opposing forces. In the case of the door, these are:

- The weight of the door itself, and

- The force supplied by the spring.

Similarly, a good draft system needs to balance:

- The gas pressure that propels beer out of the keg, through the beverage line, out of the faucet, and into your glass; and

- The total resistance that tries to keep the beer from moving forward through your kegging system.

Using our garage door analogy, pressure is like the weight of the garage door, while resistance is similar to the spring. Let’s consider each in turn.

Giving in to Pressure

Pressure from carbon dioxide serves two roles in a draft system:

- It pushes beer from the keg to your glass.

- It maintains proper carbonation in the keg.

Without top-pressure from carbon dioxide, a keg will gradually go flat as it empties, just as an opened bottle of beer does if left out on the counter overnight. And you need the right amount. Too much pressure, and the beer will gradually overcarbonate. Too little, and it will lose carbonation with time. Remember, carbonation always adjusts to match the carbon dioxide pressure in the headspace above the beer (Henry’s Law).

So, the very first step in balancing your draft system is to determine the proper carbonation level for your beer. This number may vary from one style to another (a spritzy Bavarian hefeweizen needs more carbonation than a simple English bitter), but a good, all-purpose number is 2.4 to 2.6 volumes. Most commercial kegs are carbonated in this range.

Now carbonation level varies with both applied pressure and storage temperature. So the next step is to figure out what serving pressure delivers the carbonation you want at the temperature at which your beer is stored. Most commercial setups are designed around a 38°F storage temperature with 2.6 volumes of carbon dioxide, so that’s what we’ll assume here.

You can calculate how much pressure is needed to achieve a given carbonation level at a given pressure, or you can use a chart. I prefer a chart. This one comes courtesy of the Draught Beer Quality Manual, a publication of the Brewers Association.

| Carbonation Level Chart | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| * Chart assumes sea-level elevations. Add 1 psi for every 2,000 feet above sea level. | |||||||||||

| Vol. CO2 → | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 2.9 | 3.0 | 3.1 |

| Temp. (ºF) | psi* | psi* | psi* | psi* | psi* | psi* | psi* | psi* | psi* | psi* | psi* |

| 33 | 5.0 | 6.0 | 6.9 | 7.9 | 8.8 | 9.8 | 10.7 | 11.7 | 12.6 | 13.6 | 14.5 |

| 34 | 5.2 | 6.2 | 7.2 | 8.1 | 9.1 | 10.1 | 11.1 | 12.0 | 13.0 | 14.0 | 15.0 |

| 35 | 5.6 | 6.6 | 7.6 | 8.6 | 9.7 | 10.7 | 11.7 | 12.7 | 13.7 | 14.8 | 15.8 |

| 36 | 6.1 | 7.1 | 8.2 | 9.2 | 10.2 | 11.3 | 12.3 | 13.4 | 14.4 | 15.5 | 16.5 |

| 37 | 6.6 | 7.6 | 8.7 | 9.8 | 10.8 | 11.9 | 12.9 | 14.0 | 15.1 | 16.1 | 17.2 |

| 38 | 7.0 | 8.1 | 9.2 | 10.3 | 11.3 | 12.4 | 13.5 | 14.5 | 15.6 | 16.7 | 17.8 |

| 39 | 7.6 | 8.7 | 9.8 | 10.8 | 11.9 | 13.0 | 14.1 | 15.2 | 16.3 | 17.4 | 18.5 |

| 40 | 8.0 | 9.1 | 10.2 | 11.3 | 12.4 | 13.5 | 14.6 | 15.7 | 16.8 | 17.9 | 19.0 |

| 41 | 8.3 | 9.4 | 10.6 | 11.7 | 12.8 | 13.9 | 15.1 | 16.2 | 17.3 | 18.4 | 19.5 |

| 42 | 8.8 | 9.9 | 11.0 | 12.2 | 13.3 | 14.4 | 15.6 | 16.7 | 17.8 | 19.0 | 20.1 |

Using the chart, we find that maintaining 2.6 volumes of CO2 in solution at 38°F means applying carbon dioxide at 12.4 pounds per square inch (psi) of pressure. As long as we maintain the same temperature and applied pressure, the beer in the keg will remain carbonated at 2.6 volumes from the first glass to the last.

Now here’s the kicker. The very same pressure that maintains carbonation in your beer also has to push it out of the keg and through the draft lines. That’s the essence of what we call a direct-draw draft system, which is what virtually all kegerators are. The beer is drawn directly from the keg, hence the name. And this is the fundamental trick with direct-draw systems:

In a direct-draw draft system, the pressure at which beer is pushed through the lines must be the same as that required to maintain carbonation in the keg.

More complex systems like long-draw draft setups use a blend of carbon dioxide and an insoluble gas like nitrogen to push beer at higher pressures without introducing too much CO2. But we won’t deal with those here.

Vive la résistance

So, we know our serving pressure. Great! But if we were to just hook up a faucet directly to the keg, with no beverage line in between, beer would come shooting out at a high speed, and you’d end up with a lot of foam and spilled beer. That’s where resistance comes in.

Resistance is what slows down your beer en route from keg to glass, so that beer comes out of the faucet nice and slow. And in most setups, there are only two things that provide resistance:

- Gravity

- Friction in the beverage lines

You already know about gravity. If you point a garden hose into the sky, the water eventually falls back to the earth, no matter how high you shoot it. The same is true for beer. The constant pull of gravity slows it down, and it just so happens that the amount of this pull is easy to calculate:

For every foot of height between the keg and the faucet, gravity reduces the effective pressure by about 0.5 pounds per square inch.

So, let’s say that from the chart above, you’re serving your beer at 12.4 psi. If you’re using a typical draft tower setup, the faucet might be located about two feet above the center of the keg. In that case, gravity offers about 1 psi of resistance, which means you need to supply another 11.4 psi of resistance to overcome the remainder.

The solution for most homebrewers is to simply use enough line to make up the difference, and that’s where friction in the beverage lines comes in. The amount of line you need depends on the type of line you have. Again, the Draught Beer Quality Manual offers some help:

| Type | Size | Restriction | Volume |

| Restriction values for several types of beverage line | |||

| Vinyl | 3/16” ID | 3.00 psi/ft | 1/6 oz/ft |

| Vinyl | 1/4” ID | 0.85 psi/ft | 1/3 oz/ft |

| Vinyl | 5/16” ID | 0.40 psi/ft | 1/2 oz/ft |

| Vinyl | 3/8” ID | 0.20 psi/ft | 3/4 oz/ft |

| Vinyl | 1/2” ID | 0.025 psi/ft | 1-1/3 oz/ft |

| Barrier | 1/4” ID | 0.30 psi/ft | 1/3 oz/ft |

| Barrier | 5/16” ID | 0.10 psi/ft | 1/2 oz/ft |

| Barrier | 3/8” ID | 0.06 psi/ft | 3/4 oz/ft |

| Stainless | 1/4” OD | 1.20 psi/ft | 1/6 oz/ft |

| Stainless | 5/16” OD | 0.30 psi/ft | 1/3 oz/ft |

| Stainless | 3/8” OD | 0.12 psi/ft | 1/2 oz/ft |

Let’s say, then, that you are using 1/4” inner diameter (ID) vinyl beverage line. According to the chart, it supplies 0.85 psi of resistance per foot of tubing. If you need to overcome 11.4 psi, then you’ll need 11.4 psi ÷ 0.85 psi/ft = 13 feet of beverage line or so.

Thus, in our hypothetical example, a keg of beer stored at 38°F and carbonated to 2.6 volumes of CO2 should pour perfectly if the faucet is located 2 feet higher than the keg and we have at least 13 feet of beverage line. Easy peasy.

Summary

Balancing your draft system is straightforward if you follow these simple steps.

- Choose a carbonation level that you wish to maintain in your beer. About 2.4 to 2.6 volumes of CO2 is a good number if you don’t have a good reason to do differently.

- Based on the temperature in your kegerator, select the serving pressure that will deliver that level of carbonation (accounting for elevation, if necessary, by adding 0.5 psi for every 1,000 feet above sea level). This is the pressure you need to balance.

- Account for the effects of gravity by subtracting 0.5 psi for every vertical foot between the center of your keg and the faucet. If by some chance the faucet is below the keg, then add 0.5 psi per foot of vertical instead of subtracting.

- Based on the type of beverage line you use, divide the remaining number by the resistance to obtain the number of feet of line you need.

Remember, you need only do this once, and as long as nothing changes, your system should happily serve you pint after foam-free pint. Cheers!

Dave Carpenter is the Editor-in-Chief of Zymurgy Magazine

The post A Balancing Act: How to Balance Your Home Draft System appeared first on American Homebrewers Association.

At this point, you should pick your hops into sacks and weigh them. It is always more fun to have a helper. Place a single variety into a single (screened) tray. Once your tray is full (about 1/3 up the side), set it on top of the base tray over the fan so that the tray edges align perfectly over each other. Continue to pick your hops, fill your trays and stack them up. Leave one of the trays empty to the side. I used a piece of masking tape to mark each tray to know which variety was in which tray. Next year, I may just add a plastic sleeve to the side and make up cards with the names of the varieties I grow to sort them that way (it will look much nicer).

At this point, you should pick your hops into sacks and weigh them. It is always more fun to have a helper. Place a single variety into a single (screened) tray. Once your tray is full (about 1/3 up the side), set it on top of the base tray over the fan so that the tray edges align perfectly over each other. Continue to pick your hops, fill your trays and stack them up. Leave one of the trays empty to the side. I used a piece of masking tape to mark each tray to know which variety was in which tray. Next year, I may just add a plastic sleeve to the side and make up cards with the names of the varieties I grow to sort them that way (it will look much nicer).

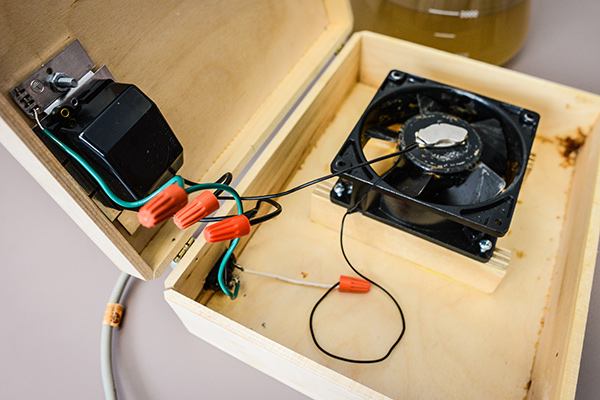

Start by centering the fan inside the box you selected. Secure the fan to the base using screws or super glue, taking care not to hinder the movement of the fan.

Start by centering the fan inside the box you selected. Secure the fan to the base using screws or super glue, taking care not to hinder the movement of the fan. Drill small holes through the box to secure the on/off switch. Do the same if using a rheostat.

Drill small holes through the box to secure the on/off switch. Do the same if using a rheostat. Once the stir plate is functioning with the ability to control the speed of the fan, seal/close the box containing the electrical components. As a test, fill the flat-bottomed starter vessel to a typical volume you will be working with and gently add the magnetic stir bar.

Once the stir plate is functioning with the ability to control the speed of the fan, seal/close the box containing the electrical components. As a test, fill the flat-bottomed starter vessel to a typical volume you will be working with and gently add the magnetic stir bar.

Harvesting Your Hops

Harvesting Your Hops

Package Your Hops

Package Your Hops